|

1905 Western Electric magazine

Wiring and Other

Electrical Regulations for Chicago Theaters

after the 1903 Iroquois Theater fire

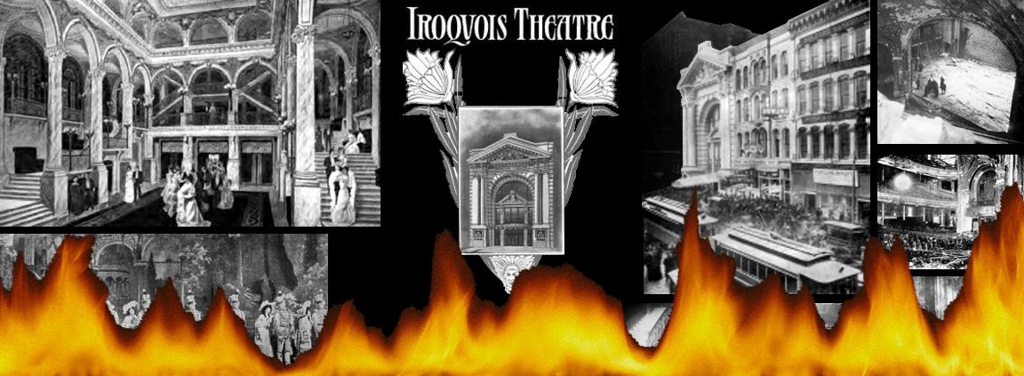

In the Iroquois Theater fire of December, 1903, Chicago had

such a terrible experience that it revised

its wiring regulations for theaters. That

fire, although originating in a spark from

an arc lamp used on the stage, was not due

so much to deficiency in existing

requirements as to laxity in their

enforcement And if there had not been

further laxity in relation to exits, stage

flues, fire-fighting apparatus, etc., there

would probably have been no loss of life

after the fire started. Nevertheless, in the

light of that terrible calamity, the

specifications for arc lamps in theaters,

for theater wiring and control of

stage flues have been entirely revised and

are now considered to afford effective

protection.

Herewith are given, for the

benefit of all interested in the subject,

the present rules and regulations of the

Department of Electricity of the city of

Chicago relating to spread and lens lamps,

as they are called, to the control of stage

flues and to the wiring of theaters.

Spread Lamps

-

Frame

The frame of lamp must be made entirely

of metal, and no wood used in connection

with it. The metal frame to be made of

galvanized steel of a thickness

equivalent to No. 24 U. S. Standard

gauge. Bottom. — Must be made of two

thicknesses of metal for strength and

be entirely closed, except that the

extending rod controlling carbon

holders may enter through the bottom,

but must be bushed in such a manner

that no opening can exist. Sides.—

Must be ribbed or fluted for strength

and be entirely enclosed; colored glass

or the like may be inserted in the

sides, provided it is held in place

both inside and outside by a metal

washer riveted tightly to the frame.

-

Back

Must be entirely enclosed, except that

the leading-in asbestos covered

conductors are to enter here, protected

with porcelain bushings; wires must be

sealed inside of bushings with asbestos.

Short porcelain bushings having the

heads inside of lamp are to be provided

and held in place by a suitable flanged

ferrule riveted to metal frame.

-

Top

Must be ribbed or fluted for strength

and be suitably ventilated with a

sufficient number of one-half-inch

openings and provided with a

substantially raised hood having

openings at sides; approved gauze wire

to be provided outside of casing to

cover openings, and substantially and

tightly riveted to metal frame to

prevent sparks being emitted from the

lamp.

-

Front Opening

Must be provided with a hinged frame in

which ground glass or other glass must

be inserted; color holder to be a part

of this hinged frame, and frame must be

so arranged that it cannot open wider

than 60 degrees; the frame of opening

must close in an approved manner, and

when closed must effectually prevent any

spark from getting out of lamp.

-

Guard

Must be provided with a one-sixteenth-

inch iron or steel guard having a mesh

not larger than one inch, and be

substantially placed over top and upper

half of sides and back of lamp frame;

this guard to be substantially riveted

to frame of lamp and to be placed at a

distance of two) inches from the lamp

frame.

-

Lamp

insulation

Fiber or rubber will not be approved as

insulation for metal parts, but mica of

suitable thickness and size will be

required.

-

Lamps on Single Standard

Not more than one arc lamp will be

permitted to be supported on a standard.

-

Switch on Standard

Knife switches controlling lamps

must be encased in one-sixteenth-inch

sheet steel box, and arranged in such a

manner that the opening or closing of

the cover of box will open or close the

switch.

-

Lugs

All stranded connections in arc

lamps and at switch and rheostat must be

soldered into lugs having ample contact

surface.

-

Carbon Holders

Carbon holders which will circularly grip the

carbons and cover at least one square inch of carbon

surface will be required.

-

Rheostat

The rheostat, if mounted on standard,

must be raised to a height of at least

three inches above floor line, and in

addition to being properly enclosed must

be surrounded with a substantially

attached metal guard having a mesh not

larger than one square inch, which guard

is to be kept at least one inch from

outside frame of rheostat.

-

Operation

It will be important to provide a competent man for each lamp,

whether "hand-feed" or "automatic," and

for the operator to remain at each lamp

until the connections leading to lamp

have been cut off. It will be necessary

in operating lamps to have them so

placed that the operator's head will be

slightly elevated above the lamp frame,

as the safe and proper care of lamps

requires looking down rather than up at

the lamp. In case of any improper

operation of arc lamps by incompetent

operators, this department will reserve

the right to order the discontinuance of

the use of arc lamps in theaters.

Lens Lamps

Lens lamps are to

be the same as spread lamps, except that the

front may be made stationary and door

provided on back or side; said door to be

provided with spring hinge to close

properly, and with a rabbet so set that it

will positively close opening.

Control for Stage Flues

Flues or vents

over stages in all Class V theaters shall be

provided with metal dampers, and shall be

operated by a closed-circuit battery or

closed lighting circuit.

Magnet operating

damper to be wound to take full voltage of

circuit it is supplied with, using no

resistance device, and must not heat more

than normal for apparatus of like

construction. Magnet must be located in loft

above scenery and be installed in an iron

box with tight-closing door.

Such dampers are

to be controlled by two switches, one at

electrician's station on the stage, and the

other at the city fireman's station on

opposite side of stage. Said switches are to

be standard single-pole switches mounted in

substantial iron boxes.

Wiring between

switches, magnet, batteries, etc., to be

standard No. 14 rubber-covered wire

installed in iron conduit. Conduit must

properly enter all boxes and be provided

with lock nuts and smooth bushings on end.

The above

apparatus must be independent of all other

devices or apparatus used to control these

dampers and its operation must not be

interfered with in anyway.

Theater Wiring

1.

All fuses used in connection with lights

illuminating parts of the house used by the

audience, such as auditorium, halls,

corridors, lobbies, stairways, etc., and

also supplementary lights on the stage, must

be enclosed in double fireproof enclosures

with a half-inch air space between

materials, and be so constructed that there

will be six inches between the fuses and the

sides and face of enclosure if open fuses

are used, and three inches for cartridge

fuses. When iron or steel are used the

materials will have to be of a thickness of

at least one-sixteenth inch.

2.

Switchboards accessible from stage

level must be protected by an approved guard

rail to prevent accidental contact with live

parts on board.

3.

Approved stagecables will be allowed to connect

stage pockets to strip lights and bunch

lights, and to extend from border lights to

fly gallery panel boxes, but no other

exposed wiring will be allowed on any stage

or in any dressing rooms, except by special

permission.

4.

All wires, whether exposed or concealed,

except those classed in the above paragraph,

must be encased in approved iron conduits

continuous from outlet to outlet.

5. Flexible cord will not be allowed in any dressing room,

scene room, property room, or on any stage

or working portion of any of the

above- mentioned houses.

6.

Molding will not be permitted to be

used.

7. Approved lugs

must be sweated to the ends of all stage cables.

8. The use of calcium lights in theaters is

strictly prohibited. All arc lamps used in

the building must meet specifications of

this department, and are not to be used

until stamped "approved" by the city

electrician.

9. A competent attendant must be constantly kept in

charge of each arc lamp during the entire

time such lamp is in use or connected to the

live circuits.

10.

Pockets for receptacles must contain

no gas piping, and must be rendered

absolutely fireproof, and must be kept open

at the bottom so that no accumulation of

rubbish or dust will collect therein.

Pockets must be so constructed that live

parts of plug will be protected by floor

ledge and must be cleaned out before every

performance.

11.

Pocket receptacles, when permitted,

must be wired for a capacity of at least 15

amperes.

12. All stage borders must be constructed of

galvanized or enameled iron having a

thickness of not less than No. 20 gauge, and

must be constructed so that the flanges of

reflectors will protect the lamps. Borders

must be suspended by wire rope. Fuses must

not be placed on borders.

13.

Strips are to be constructed the same

as the border lights above, except that in

the proscenium strips a wire mesh will be

required to keep the curtains and scenery

from coming in contact with lamps. Other

strips are to have iron bands so constructed

that they will protect the lamps.

14.

Footlights are to be mounted in an

iron trough constructed of galvanized or

enameled iron not less than No. 20 gauge.

15.

General lamps about the stage and

dressing rooms must be provided with

approved guards. Sockets or lamps will not

be permitted on a canvas or other cloth

setting.

16. Plugging boxes must be of an approved type.

17. Drop chandeliers will not be allowed in

scene setting unless a special permit has

been obtained for use in each setting.

18. The use of

any special electrical effect, such as

lightning, etc., must be approved before

being used.

19.

All lights in halls, corridors, lobby, or any other

part of the building used by the

audience, except the auditorium, shall be

controlled by a separate shut-off located in the lobby,

and controlled only in that particular

place.

20.

Every portion of the building devoted to the use

or accommodation of the public, also all

outlets leading to the streets and including

all open courts, corridors, stairways, exits

and emergency exit stairways

shall be well and properly lighted during

every performance, and the same shall

remain lighted until the entire audience has

left the premises. One 16-candlepower

incandescent lamp for every 400 square feet

of floor space will be considered sufficient

for illumination.

21.

All stairways and corridors shall be

supplied with asupplementary lighting system of

electricity, gas or sperm oil and such

system shall be independent of all other

lights in such building, and shall be in

operation during the entire period such

theater is open to the public and until the

audience has left the building.

22.

All alterations to electrical equipment, and all

new work to be installed or used on each

attraction must be reported by manager of

house and permits be secured before any work is

done. (This to include sign work.)

|